Our services

As creators of solutions on a day-to-day basis, our employees are with you from prototype design to mass production.

Keynumbers

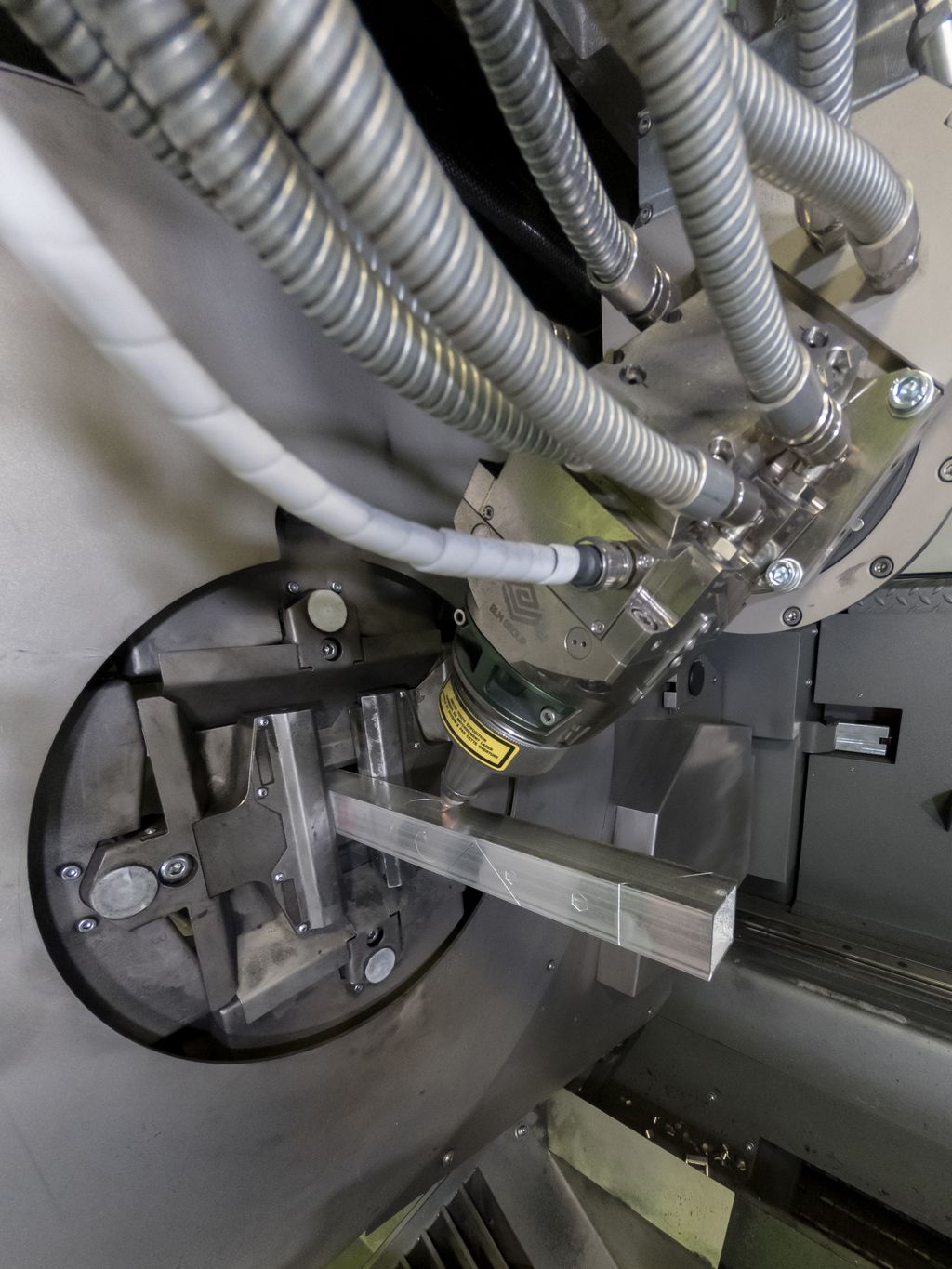

40

High-performance machines10,000 m2

of workshop space dedicated to metalworking+ 3.400

Parts cut per day1

Innovative management software program

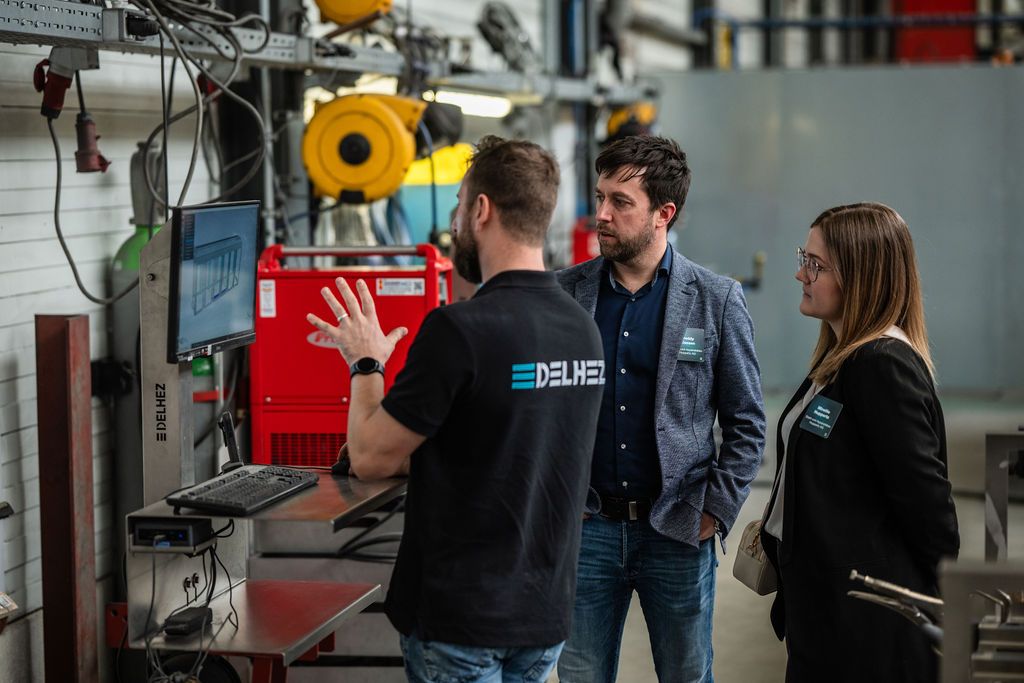

Management from A to Z

Our team can help you design your metal part

Our project managers will advise you right from your metal parts’ prototype stage. Drawing on their knowledge and experience, they will develop a specific manufacturing process to facilitate the mass production of your parts, and adapt the tooling where necessary.

Strict quality control

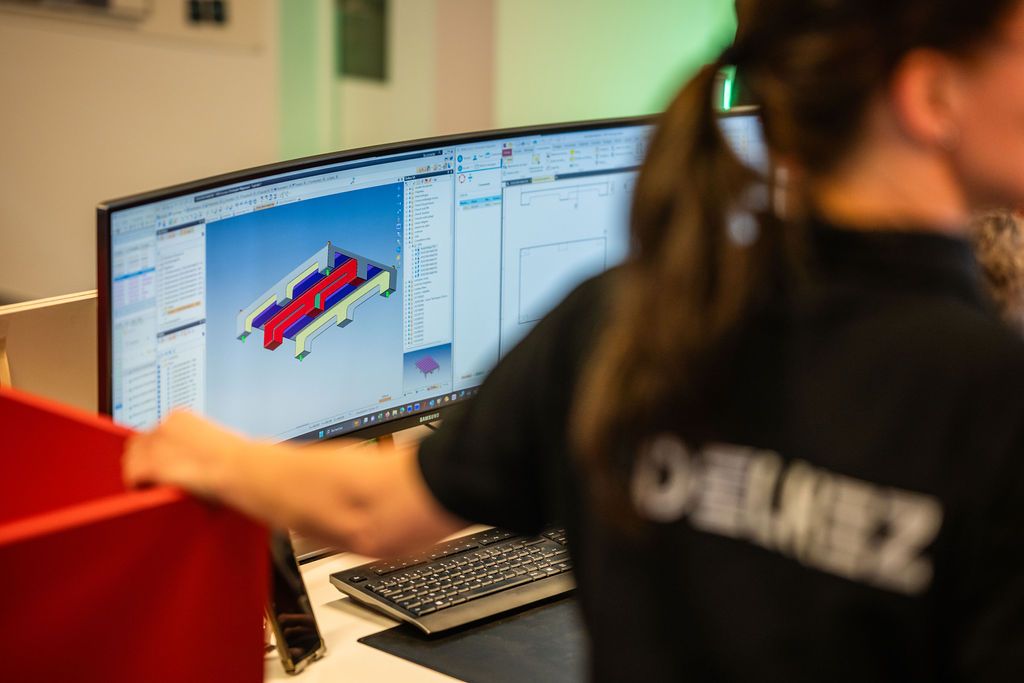

Software created especially for Delhez

On a day-to-day basis, we use software called the Delhez Production Management System (DPMS). This custom-developed interface is used to manage every stage in the production of the metal parts entrusted to us, and to ensure that they comply with a very strict charter. Our customers are guaranteed a comprehensive overview of the manufacturing process and impeccable quality for the finished product.

To meet our customers’ needs as effectively as possible, we regularly improve the DPMS and are continuing to develop it further.